The FlexiPull Drawer Scoop Design Brief

Kacey Roehrich

Background

The bathroom is often the smallest room in most homes and apartments. Narrow bathroom doorways often mean a wheelchair cannot fit into the room, and if one can, there is often not enough space to maneuver in the room without bumping into something. Furniture and fixtures are all subject to collisions while maneuvering a wheelchair in a bathroom. One object that is often bumped into in bathrooms is drawer handles or drawer pulls. Drawer handles are a piece of hardware that is both functional and decorative, coming in many shapes, sizes, and finishes. Drawer handles are typically made of metals such as aluminum, brass, and stainless steel, all of which are unforgiving when bumped into and can cause harm to the individual and damage to the wheelchair or handle itself. Finding a style and material that is safe and functional for individuals who use a wheelchair and have limited hand function is an unmet need. Low-profile drawer handle solutions address the need to eliminate an object that is unsafe to bump into, but for individuals with limited hand function, these solutions are difficult to operate. On the other hand, as a drawer handle becomes larger and protrudes further from the face of the drawer, it is easier to operate with limited hand function, but it increasingly becomes an obstacle.

The project's client has a specific setup in the bathroom. The client's stack of drawers was designed for use without external hardware. The design keeps the face of the drawer smooth and free from handles that could catch on his wheelchair, but with limited hand function, the drawers are difficult to open. The client's solution was to put drawer pulls on the drawers, thus making it possible to independently open the drawers but added objects that get caught on his wheelchair. When the client opens these drawers, he is positioned at the sink, to the left of the drawers. When in this position relative to the drawers, he has found rotating the drawer handles ninety degrees, as shown in Figure 1, and using the side of his hand to pull in a sideways and outward motion is the best method for him to open the drawers. While this setup works, it is worth mentioning that the client often bumps into the drawer pulls or catches his wheelchair on them while maneuvering in the bathroom. The top and bottom drawers in Figure 1 have had their handles broken off, and the three middle handles have been bent out of shape and reshaped for the photo.

Problem Statement

Bathrooms have limited space to maneuver in, and navigating around drawers and drawer handles further reduces the amount of maneuverable space. Currently, no drawer handle solutions are low profile or safe to bump into with a wheelchair and operable for individuals with limited hand function. I aim to create a drawer handle for individuals who use a wheelchair and have limited hand function that is functional and does not create an unsafe and damaging obstacle so they can safely maneuver in rooms with limited space.

Research Question

What is the best shape and material for a drawer handle that is safe for individuals and their wheelchair when impacted and operational for users with limited hand function? This project aims to design a drawer handle for users who use a wheelchair and have limited hand function that does not cause harm or damage to them or their wheelchair and can be operated comfortably and efficiently.

Methods/Approach/Solutions Considered

After identifying the need for an accessible drawer handle, I interviewed the client to collect additional information. The client has not found a drawer pull style that works better than the current handle solution. He has found using the side of his hand to pull on drawer pulls is the best and easiest method. He prefers drawer pulls that always stick out rather than ones that retract

or lie flush when not in use and prefers to interact directly with the drawer pulls instead of using an additional device to grab onto the drawer pulls.

When drafting my first designs, I decided to use a flexible material. Creating a drawer pull that always sticks out from the drawer face was unavoidable since the client prefers them that way, so it is best if they are flexible and elastic. When the client bumps into or catches his wheelchair on my drawer pull design, the drawer pull should collapse towards the face of the drawer or stretch until he has moved past it and then return to its shape. Flexibility and elasticity will make a drawer pull more forgiving when bumped into and not cause damage to the client or his wheelchair.

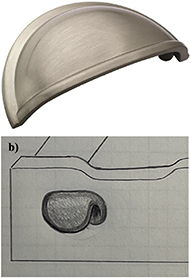

I began my design approach by comparing common drawer pull shapes to determine which may be best for the client. I liked the quarter-dome shape of a traditional scoop pull1, shown in Figure 2a, because it does not have corners or edges that could catch on a wheelchair. Operating these scoop pulls can be difficult for users with limited hand function because the design requires rotating the wrist so the palm faces upwards and then inserting the fingers into the scoop. One initial design sketch, based on a traditional scoop pull and shown in Figure 2b, kept the overall shape but opened the sides of the scoop. With open sides, this scoop design can be gripped from the sides and the bottom.

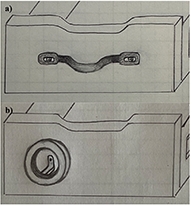

A second design, inspired by traditional U-shaped handles, is shown in Figure 3a. This design featured slots around the screwheads so the handle could slide toward the face of the drawer upon impact. A third design, shown in Figure 3b, aimed to maximize the access points for the client to grip the drawer pull.

The design is ring-shaped so the client can grip the drawer pull from anywhere on the ring, irrespective of whether they are positioned to the side of the drawers or directly in front of them.

Next, I received feedback on my design ideas from the client, my professors, and my classmates. Everyone who provided feedback supported the choice for a flexible material. Other comments voiced concern over the size of the ring design. A ring large enough to be gripped comfortably would likely stick out far enough from the face of the drawer to get caught on clothes and wheelchairs. A similar comment was made about the design inspired by U-shaped pulls. There were concerns that a flexible U-shaped pull would have the same issues as one made of stainless steel. As the size of the U increases, the pull becomes easier for users to fit their hand in, but it also sticks out further. The client liked the scoop design best and recommended rotating it ninety degrees counterclockwise to match the orientation of his current drawer pulls.

Description of Final Approach and Design

I created a model of my scoop pull in Fusion360. The scoop pull is 1.7 inches tall, 0.186 inches at the thickest point, and protrudes 1.5 inches from the face of the drawer. After confirming the dimensions of the client's drawers, I chose mounting hardware with appropriate measurements. I decided to use stainless steel machine screws and binding barrels so an impact with the FlexiPull Drawer Scoop will not pull out the screws from the face of the drawer and so the hardware on the inside of the drawer is smooth to the touch. Next, I 3D printed the scoop pull in powder-based thermoplastic polyurethane (TPU), fused deposition modeling (FDM) TPU, and polypropylene. All three materials are flexible plastics, but since I did not know which material would have the balance of flexibility, elasticity, and stiffness I was aiming for, I made a prototype from each. After handling the prototypes, polypropylene was too flexible, and powder-based TPU was too stiff, but FDM TPU had the right balance. The final prototype is made from FDM TPU with 80% infill. The edge is reinforced to give the scoop extra rigidity and add ornamental detail. The part of the scoop pull that sits against the drawer is 1/16th of an inch thicker than the rest of the scoop so the screw heads can be countersunk. Images of the final prototype are shown in Figure 4.

Outcome

To confirm that the user needs were met and to determine overall user satisfaction, the FlexiPull Drawer Scoop underwent a battery of verification and validation tests. The FlexiPull Drawer Scoop needs to be water resistant since it will be used in the bathroom and subject to wet hands and humid conditions. A bench-top test based on the American Society for Testing and Materials (ASTM) standard D5702 was performed to evaluate the water resistance of FDM TPU. A sample of FDM TPU was dried in an oven, cooled in a desiccator with calcium chloride, and submerged in a twenty-three degrees Celsius water bath for twenty-four hours. After twenty-four hours, the sample was removed from the bath and a percent water absorption of 1.08% was calculated from the initial and final mass of the sample.

The next verification tests evaluated how much force could be applied to different points on the FlexiPull Drawer Scoop. Push forces were applied to the outer face of the scoop to simulate frontal impacts and to the inner face to simulate getting caught on caster wheels and forks. Pull forces were applied to the edge of the scoop to evaluate how much force could be applied to the FlexiPull Drawer Scoop before it stretched too far to be functional. While performing these tests, I also observed how well and how quickly the FlexiPull Drawer Scoop recovered its original shape once the force was removed. To fully flex the FlexiPull Drawer Scoop so the scoop contacted the face of the drawer took between fifteen and twenty-nine pounds, depending on the angle at which the force was applied, see Figure 5. To fully stretch the FlexiPull Drawer Scoop so the scoop was parallel with the face of the drawer took between fourteen and fifteen pounds. When applying pulling forces, it took seven pounds of force before the FlexiPull Drawer Scoop is straightened and the hook slides off. After the force was removed, the FlexiPull Drawer Scoop immediately sprang back to its original shape. There was no residual deformation of the FlexiPull Drawer Scoop.

The validation tests were completed by the client on his set of bathroom drawers. The client was satisfied with the size, shape, and color of the FlexiPull Drawer Scoop. The increased size of the FlexiPull Drawer Scoop compared to the previous drawer pulls provided more surface for the client to grip. The FlexiPull Drawer Scoop met the Americans with Disabilities Act (ADA) guidelines for operable cabinet and drawer hardware, specified in Section 3093 , by being operable with one hand and not requiring tight grasping, pinching, or twisting of the wrist. In complying with the ADA guidelines, the FlexiPull Drawer Scoop also met the need of being operable with limited hand function. Since the client is most often positioned at the sink next to the drawers, the FlexiPull Drawer Scoop needed to be operational from that position. Unlike the previous drawer pulls which could only be used when the client was positioned at the sink, the client could also open the drawers when positioned in front of them or at a forty-five-degree angle. The client had confidence in the strength of the FlexiPull Drawer Scoop and did not worry that he was going to permanently deform or break them after an impact. Despite the flexibility of the FlexiPull Drawer Scoop, it has sufficient stiffness too. The client reported roughly one-eighth inch of flex when he pulls on the FlexiPull Drawer Scoop, but it remains stiff enough as he pulls on it to open the drawer. The client tested frontal impacts between the FlexiPull Drawer Scoop and his wheelchair, impacts on the FlexiPull Drawer Scoop with his knee, and swiping the FlexiPull Drawer Scoops with his caster wheels and forks. In each case, the FlexiPull Drawer Scoops flexed out of the way without causing damage to the client or his wheelchair and returned to their original shape.

Cost

The total cost estimate for a set of five FlexiPull Drawer Scoops plus mounting hardware is $54.98. The cost to 3D print one FlexiPull Drawer Scoop is $7.60, so it costs $38 to print five. The stainless-steel binding barrels cost $12.84 for ten binding barrels. The stainless-steel machine screws cost $4.14 for twelve screws, though only ten were needed.

Significance

This project intends to create a bathroom drawer handle that increases the accessibility to drawers and decreases the obstacle created by standard drawer hardware. Increasing accessibility to bathroom drawers for individuals with limited hand function increases their independence and alleviates frustration during tasks essential to personal care. The client said he did not realize the difference that having a more exaggerated scoop would make, but after using the FlexiPull Drawer Scoop for a few days, the improvement over the previous drawer pulls was clear. Previously, the client needed to be aware of how much clearance he had to move around his bathroom. If he did not have enough clearance and hit the drawer handles, the handles would get broken and bent out of shape, his wheelchair would get scraped, and he would bruise and cut his knees. With the FlexiPull Drawer Scoop, the client can freely move around his bathroom and does not need to be as mindful of his clearances with the drawers. If he does hit the FlexiPull Drawer Scoops, they will move out of his way without causing any damage, then spring back into place and be ready for use.

References

- Amerock. (n.d.). Cup Pulls Collection 3 in (76 mm) Center-to-Center Satin Nickel Cabinet Cup Pull. homedepot.com. https://www.homedepot.com/p/Amerock-Cup-Pulls-Collection-3in-76-mm-Center-to-Center-Satin-Nickel-Cabinet-Cup-Pull-BP53010G10/202247532.

- Standard Test Method for Water Absorption of Plastics. doi:10.1520/D0570-22.

- Americans with Disabilities Act. ADA Standards for Accessible Design. ADA.gov https://www.ada.gov/law-and-regs/design-standards/2010-stds/#309-operable-parts (2010).

Acknowledgments

I would like to acknowledge the efforts of my professors Alexandra Delazio, Todd Hargroder, Dr. Dave Brienza, and the teaching assistant Taychapat Makkong, and thank each of them for their instruction, feedback, and encouragement during this project. Special thanks to Todd Hargroder, my primary client, for his feedback throughout the design and testing processes.